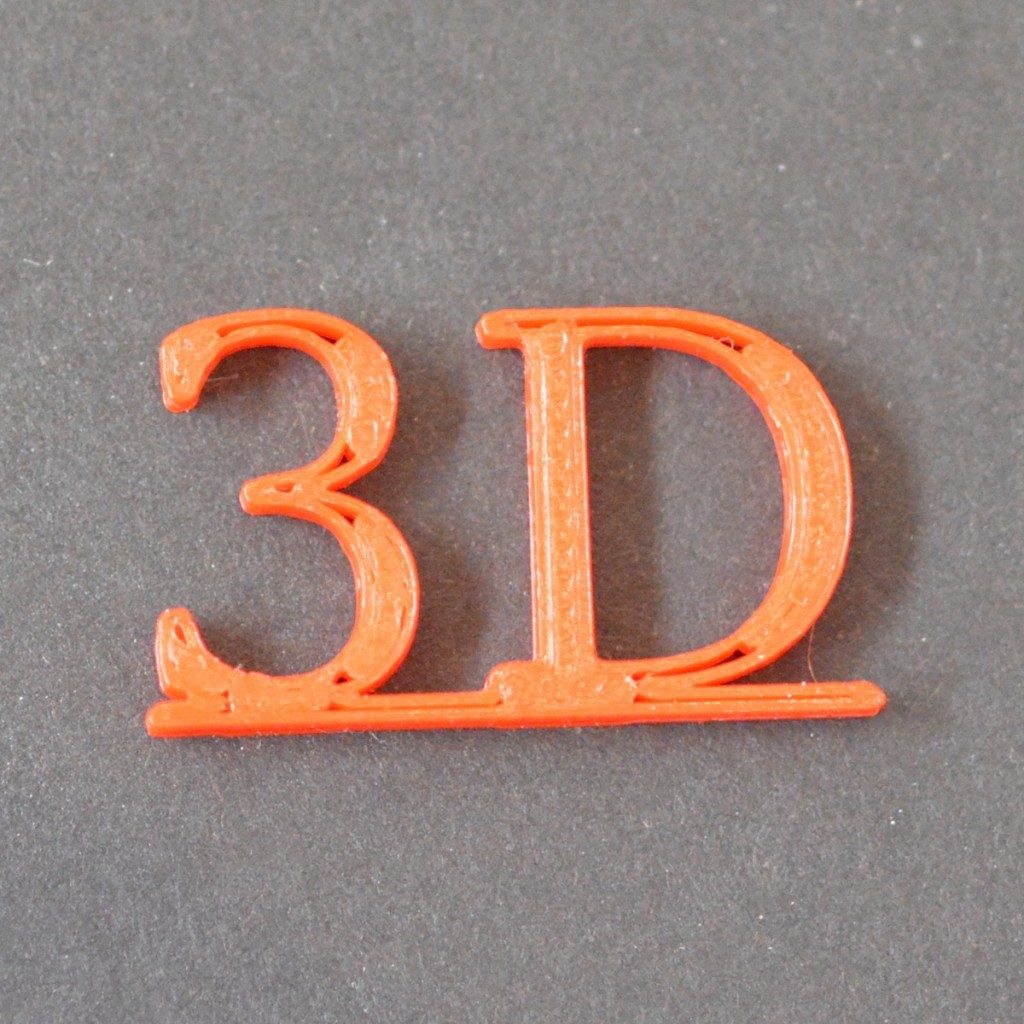

3d printing base layer gaps

The nozzle extrudes molten filament on the printer build surface to lay the first layer in additive manufacturing. Affordable functional prototypes production parts in more than 70 metals and plastics.

Gaps In 3d Prints How To Fix Avoid Them All3dp

The problem with 3D printing first layer.

. It is followed by subsequent layers laid upon layers until the 3D printed object is complete. As the foundation to your whole print it is essential in providing proper adhesion to the build plate. Use M92 EXXXX to increase the extruder stepsmm in the start G-code then set it back to normal in the layer.

If you have it higher than this you can experience layer separation. A flow rate value that is too high. Read on for some tips and tricks and say goodbye to 3D printing first layer problems.

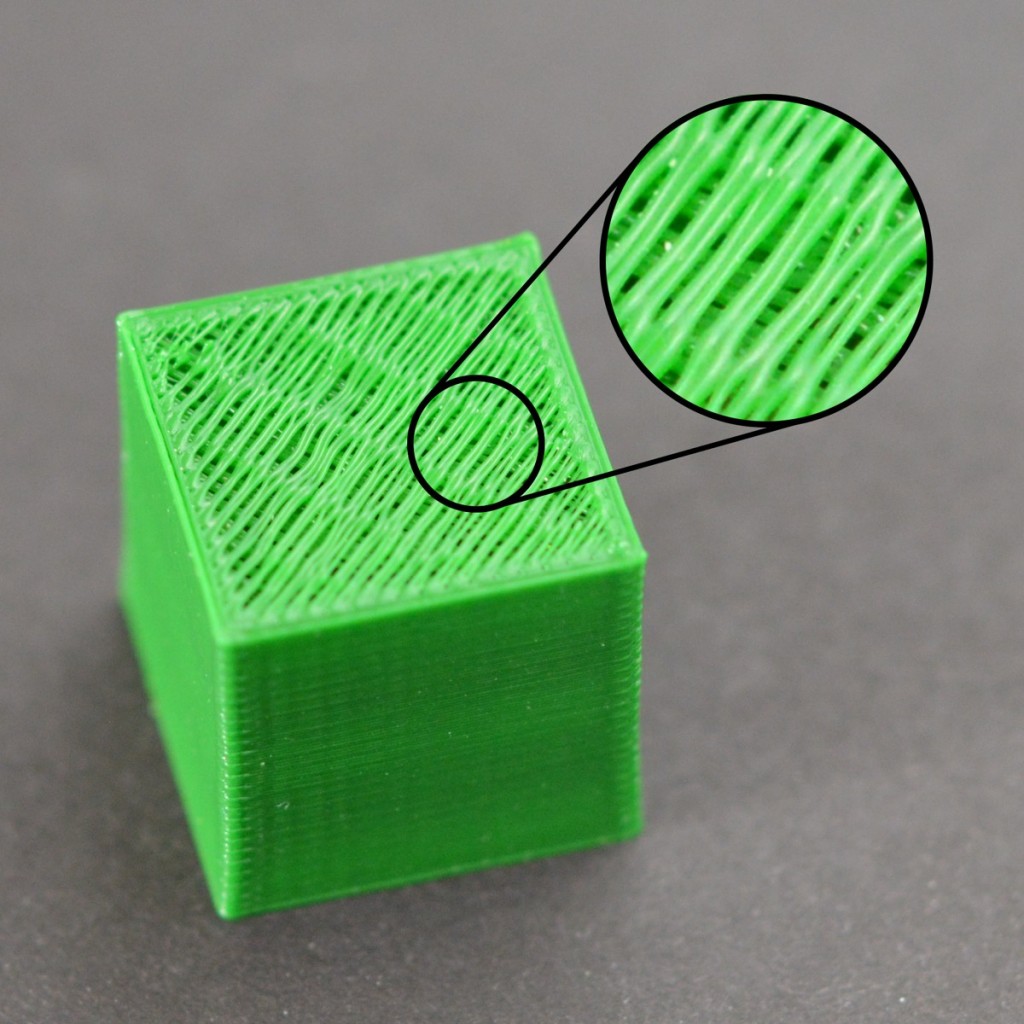

The corners of a 3d printed square object are rounded. 3D print layers. If your infill percentage is very low there will be large air gaps in your infill.

The first layer of your print is probably the most important layer. A 3D printed raft is basically a throwaway horizontal surface that sits under your object to help with bed adhesion. Since you said nozzle I expect you mean FDM 3d printing.

Thu Sep 15 2016 801 pm. If you reduce the height of the layers then there will be a squashing effect as the material extrudes. For example if you only use a 10 fill rate the remaining 90 of the printouts will be hollow.

Ad From prototype to production get quality parts at consistently low prices. Unless Im printing very slow 15 mms Im getting gaps between the lines. The photo shows a layer printed in only 30 mms and it seems like every second line is too thin which makes the gaps.

With a 3D printer you should set the height of the layers at around 80 of your printers nozzle diameter. Whats the 3D Printing Problem. For example if you are using an infill percentage of only 10 the remaining 90 of the interior of your part would be hollow and this would create some very large air gaps.

Especially in corners with. Change the Z offset either in software or by adjusting the endstop. Updated Feb 25 2022.

Many common 3D printing problems stem from a poor first layer. 3D printing hobbyists need to be extra vigilant when printing the first layer. By Lucas Carolo.

Ive even tried to increase extrusion to 200 without any changes. Bring the nozzle closer to the bed for the first layer. So what causes a rough first layer on a 3D printed model.

If the foundation is not strong enough holes and gaps will appear between the layers. It worked right out of the box with the exception of one of the screws on the filament holder on the extruder the ones with the screws popping off. Its made up of a predetermined number of layers with a specific infill percentage that extends a specific distance away from the sides of your object.

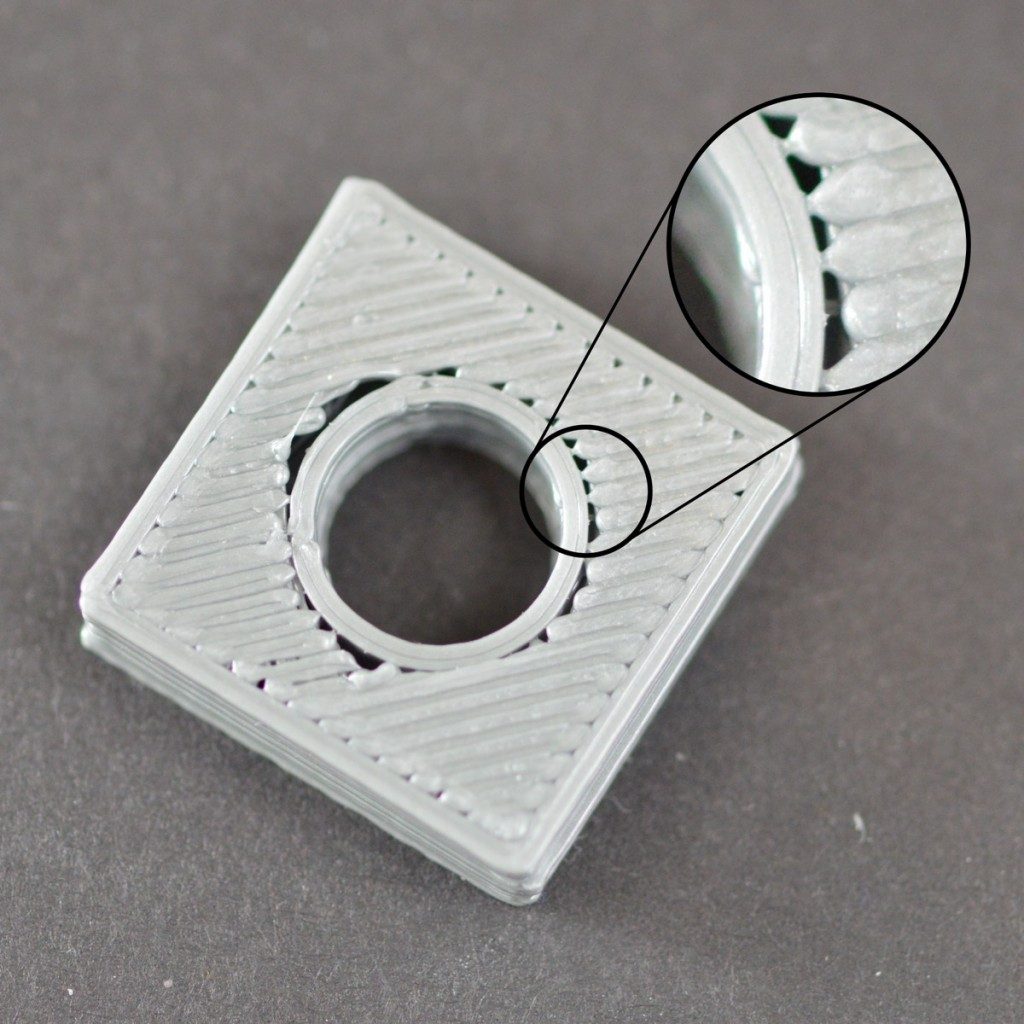

At the base of the model the print bends upwards until its no longer level with the print platform. Custom Shell Gear Print thin walls Checkbox Close Print thin walls. This can also result in horizontal cracks in upper parts.

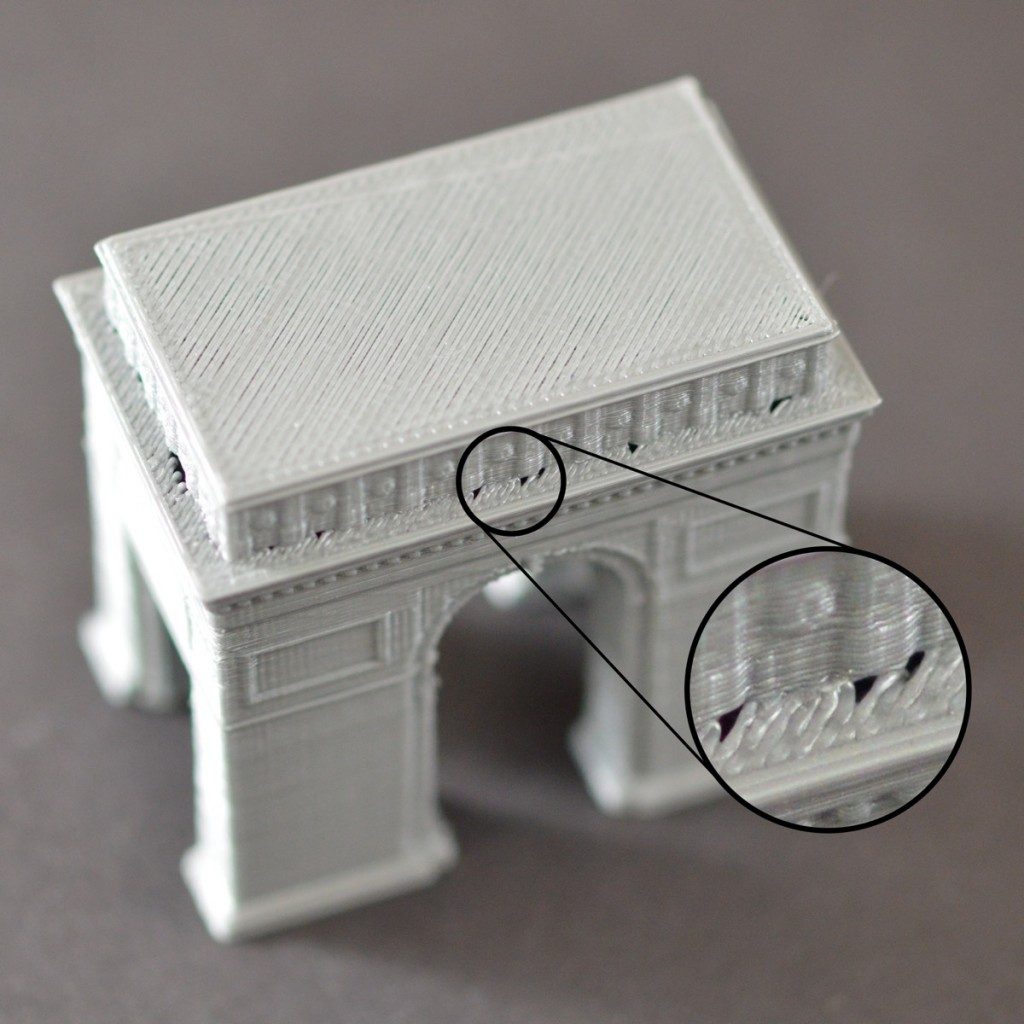

This is the most appropriate fix for your issue. I Cannot Print Model X. Gaps in 3D prints are annoying defects that mess up how parts look and work.

A raft is a thicker base layer that provides extra stability for 3D prints. Strange gaps on layers when printing. Typically you would use one 1 outline of gap between the parts.

Use A Raft To Avoid 3D Printing Layer Shifting. In 3D printing each layer is built on the previous layer. Some materials like ABS greatly benefit from the use of a raft.

It may be a good idea to calibrate the extruder and make sure the filament when asked to feed 10cm is actually feeding 10cm. An outline is usually equal to the size of the nozzle. You can see where to find this option in the following slicers.

This can happen for a number of reasons including bad filament quality incorrect filament diameter and temperature settings and insufficient print platform heating time. Just got my refurbished Robo-3D R1 this week and Im quite happy with it as an upgrade from my Printrbot Simple Metal. You can combine this with an increased first layer height.

Most 3D print gaps occur in this stage. Reduce the layer height. There are 3 places you can find gaps in your 3D print so feel free to skip down to the section which is.

Printer settings Advanced mode Layers and. However the amount of plastic used for printing will cause the holes and gaps problem so the balance between the strength of the base and the amount of plastic used needs to be balanced. The solid layer at the top of the printout needs to be printed on this basis.

3D Printing first layer peeling is an issue caused by the first 3D printing layer not properly adhering to the following layers. A Z offset value that is too low. Gaps in 3D prints are usually caused by under-extrusion printing temperature and speed.

The fill inside the print will become the basis of its upper layer. Under-extrusion results in thin layers in layers with unwanted gaps or in missing layers entirely see 3D Printing Problems 5. The solid layers at the top of your part will need to print on top of this foundation.

The first layer plays a huge role in a prints success. Check out this guide for easy fixes and how to avoid them. Sometimes excessive slip or the temperature being a touch low can cause it to not flow smoothly out the nozzle.

I havent printed in a while and now I cant get any good layers. The radius of that rounding would be half your nozzle diameter ie. Edit process settings Advanced Internal thin wall type Allow gap fill.

Areas with Missing Material. The factors that can cause a rough first layer on a 3D printed model are as follows. Re-leveling your bed slightly increasing the printing temperature or decreasing the speed can reduce any gaps in the layers of your 3D printed model.

A first layer height that is too low. Inside Fill thin walls. It can be helpful for printers that have trouble with bed adhesion or when printing with materials that are prone to warping.

Fill rate is too low. If the fill rate is very low there will be a lot of empty space in the fill. A build plate printer bed that is not level.

Aside from feeding the material and spreading the 3D design 3D printing is.

Gaps In 3d Prints How To Fix Avoid Them All3dp

Troubleshooting Gaps Holes In The 3d Print Walls 3d Printing Stack Exchange

Gaps In 3d Prints How To Fix Avoid Them All3dp

3d Printing Troubleshooting Guide Layer Separation Youtube

Gaps Between Infill And Outline

Gaps In 3d Prints How To Fix Avoid Them All3dp

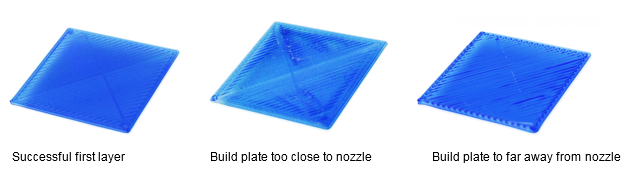

First Layer Issues Prusa Knowledge Base

Extrusion Multiplier Calibration Prusa Knowledge Base

3d Printer Dummies Guide Print Not Sticking To The Build Plate

Troubleshooting Guide To 19 Common 3d Printing Problems Part One Geeetech Blog

Gaps In 3d Prints How To Fix Avoid Them All3dp

Ultimaker Cura How To Fix Wall Separation In 3d Prints Gaps In Between Wall Perimeters 3d Printing Stack Exchange

Cura 4 8 Slicer Tips For Eliminating Gaps In Your 3d Prints Youtube

Troubleshooting Gaps Holes In The 3d Print Walls 3d Printing Stack Exchange